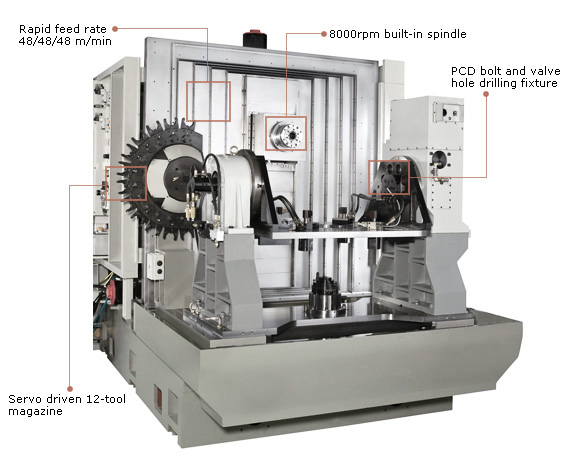

Alloy Wheel Machining Centres

Vcenter-H26W

Following the increasing demands for the rear boring on wheel valve hole, Vcenter-H26W is launched to meet this requirement for OEM wheel manufacturers to cover wheel size 13"~ 26" machining.

Advanced solution for boring the PCD bolt and valve holes from BOTH sides assures higher position accuracy on wheels 21 to 26-inches

3-axis moving column design features high rapid feed rate 48/48/48 m/min

| ITEM | Units | Vcenter-H26W |

|---|---|---|

| X axis travel | mm (inch) | 720 (28.34) |

| Y axis travel | mm (inch) | 720 (28.34) |

| Z axis travel | mm (inch) | 520 (20.47) |

| Spindle nose to table | mm (inch) | 170~690 (6.69~27.16) |

| Wheel range - PCD & valve holes only | 24” (opt. 26”) | |

| Wheel range - decoration holes | 24” (opt. 26”) | |

| Spindle motor (cont./30min) | kW (HP) | L: 15/18.5 (20/25) H: 18.5/22 (25/29.5) |

| Spindle speed | rpm | 8000 (built-in) |

| X/Y/Z axis rapid feedrate | m/min (IPM) | 48/48/48 (1890/1890/1890) |

| X/Y/Z axis feed motor | kW (HP) | 4.5/4.5/5.5 (6/6/7.4) |

| Max. tool length | mm (inch) | 350 (13.8) |

| Max. tool weight | Kg (lbs) | 7 (15.47) |

| Max. tool diameter [without adjacent tools] | mm (inch) | 80[125] (3.15[4.92]) |

| Tool changeover time | sec | 10 (T-T), 15 (C-C) |

| Magazine capacity | 12 | |

| Coolant tank | Liter (gallon) | 550 (145) |

| Power requirement | kVA | 45 |

| Controller | Fanuc | 0i-MD |

| Machine dimension (incl. chip conveyor and stepper) | mm (inch) | 3540 x 4859 x 2645 (139.4 x 191.3 x 104.2) |

| Machine weight | Kg (lbs) | 10500 (23100) |