Page 15 - Vcenter-AX350AX800 (5 axes)

P. 15

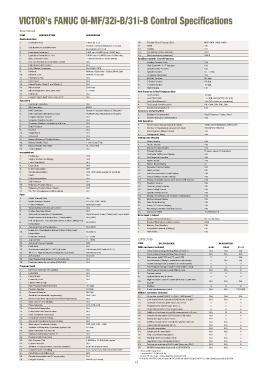

VICTOR's FANUC 0i-MF/32i-B/31i-B Control Specifications

Standard

ITEM SPECIFICATION DESCRIPTION

Controlled Axes

1. Controlled Axes 3 Axes (X, Y, Z) 30. Program Stop / Program End M00 / M01 / M02 / M30

Position / Linear interpolation / Circular 31. Reset Std.

2. Simultaneous Controlled Axes

interpolation (3 / 3 / 2) 32. Scaling G51

3. Least Input Increment 0.001 mm / 0.0001 inch / 0.001 deg. 33. Coordinate System Rotation G68

4. Least Input Increment 1 / 10 0.0001 mm / 0.00001 inch / 0.0001 deg. 34. Tilted work plane command G68.2

5. Max, command value Ô99999.999mm (Ô9999.9999in) Auxiliary Spindle Speed Function

6. Fine Acceleration & Deceleration Control Std. 1. Auxiliary Function Lock Std.

7. High Speed HRV Control Std. 2. High Speed M / S / T Interface Std.

8. Inch / Metric Conversion Std. (G20 / G21) 3. Spindle Speed Function Std.

9. Interlock All Axes / Each Axis / Cutting Block Start 4. Spindle Override 50 ~ 120%

10. Machine Lock All Axes / Each Axis 5. 1 st Spindle Orientation Std.

11. Emergency Stop Std. 6. M Code Function M3 digit

12. Over-travel Std. 7. S Code Function S5 digit

13. Stored Stroke Check 1 and Check 2 Std. 8. T Code Function T2 digit

14. Mirror Image Each Axis 9. Rigid tapping Std.

15. Mirror Image M73, M74, M75, M76 X, Y Axes

16. Follow-up Std. Tool Function & Tool Compensation T8 digit

Tool Function

1.

17. Position switch (with Victo's own PLC) Std.

2. Tool Offset Pairs Ô6-digit, 400 (0i/32i), 999 (31i)

Operation 3. Tool Offset Memory C Std. (D/H codes are separated)

1. Automatic Operation Std. 4. Tool Length Compensation G43-G44, G45-G48, G49

2. MDI Operation MDI B 5. Cutting Compensation C Std.

3. DNC Operation Reader / Puncher Interface is Required Accuracy Compensation

4. DNC Operation with Memory Card PCMCIA Card Attachment is Required 1. Backlash Compensation Rapid Traverse / Cutting Feed

5. Program Number Search Std. 2. Stored Pitch Error Compensation Std.

6. Sequence Number Search Std. Edit Operation

7. Sequence Number comparison and stop Std. 1. Part Program Storage Length (in total) 1280m (512KB) (0i/32i), 2560m (31i)

8. Buffer Register Std. 2. Number of Registerable programs (in total) 400 (0i/32i),1000 (31i)

9. Dry Run Std. 3. Part Program Editing / Protect Std.

10. Single Block Std. 4. Background Editing Std.

11. JOG Feed Std.

12. Manual Reference Position Return Std. Setting and Display

13. Manual Handle Feed 1 Unit / Each Path 1. Status Display Std.

14. Manual Handle Feed Rate X1, X10, X100 2. Clock Function Std.

15. Z Axis Neglect Std. 3. Current Position Display Std.

4. Program Display Program name 31 characters

Interpolation 5. Parameter Setting and Display Std.

1. Positioning G00 6. Self Diagnosis Function Std.

2. Single Direction Positioning G60 7. Alarm Display Std.

3. Exact Stop Mode G61 8. Alarm History Display 25

4. Exact Stop G09 9. Operation History Display Std.

5. Linear Interpolation G01 10. Help Function Std.

6. Circular Interpolation G02, G03 (multi-quadrant is possible). 11. Run Hour and Parts Count Display Std.

7. Dwell G04

8. Helical interpolation Std. 12. Actual Cutting Feedrate Display Std.

13.

Std.

Display of Spindle Speed and T Code At All Screens

9. Skip Function G31 14. Graphic Function Std.

10. Reference Position Return G28 15. Dynamic graphic display Std.

11. Reference Position Return Check G27 16. Servo Setting Screen Std.

12. 2 nd / 3 rd / 4 th Reference Position Return Std.

17. Spindle Setting Screen Std.

Feed 18. Display of Hardware and Software Configuration Std.

1. Rapid Traverse Rate Std. 19. Multi-Language Display Std.

2. Rapid Traverse Override F0, 25%, 50%, 100% 20. Data Protection Key Std.

3. Feed Per Minute G94 (mm / min) 21. Erase CRT Screen Display Std.

4. Tangential Speed Constant Control Std. 22. Machining Condition Selecting Screen Std.

5. Cutting Feed rate Clamp Std. 23. Color LCD / MDI 10.4"(0i/32i/31i)

6. Automatic Acceleration / Deceleration Rapid traverse: linear; Cutting feed: exponential Data Input / Output

7. Rapid traverse Bell–shaped Acc. / Deceleration Std. (G00) 1. Reader / Puncher Interface RS-232 interface

Bell–shaped Acc. / Deceleration Before & After Cutting Feed

8. Std. (G01) 2. External Work piece number search 9999

Interpolation 3. Memory Card Interface Std.

9. Automatic Corner Deceleration Std. (G64) 4. Embedded Ethernet (10Mbps) Std.

Linear Acc / Deceleration Before & After Cutting Feed

10. Std. (G01) 5. USB device Std.

Interpolation

11. Feed rate Override 0 ~ 150%

12. Jog Override 0 ~ 100% OPTIONS

13. Automatic Corner Override G62. ITEM SPECIFICATION DESCRIPTION

14. Feed Stop Std. With hardware included

15. AI contour control (AICC, G05.1) (in total) 200 blocks (0i/32i with AICC-2) 1. Conversational programming (Manual Guide i) 0i-M 32i-B 31i-B

Std.

Std.

Std.

16. AICC-2 + High speed processing (G05.1) (in total) 600 blocks (31i) 2 Conversational programming (Super Cap i) N.A. N.A. N.A.

17. Jerk Control Std. (31i) 3. Data server (with PCB and CF card 1GB) Std.

18. Rigid Tapping Bell–Shaped Acc./Deceleration Std. 4. Fast Ethernet (100Mbps, available in Data server) Std. Std.

19. Feed rate clamp by arc radius (G02/G03) Std.

5. Tool life management (2 buttons on control panel)

Program Input 6. Part Program Storage Length 5120m (2MB in total)

1. EIA / ISO Automatic Recognition Std. 7. Part Program Storage Length 8MB in total N.A. N.A.

2. Label Skip Std. 8. Program restart

3. Parity Check Std. 9. Optional block skip 9 blocks

4. Control In / Out Std. High Precision Contour Control (HPnanoCC, with RISC

5. Optional Block Skip 1 10. board)* 1 N.A. N.A. Std.

6 Max. Programmable Dimension Ô8-Digit 11. Profibus

7. Program Number O4-Digit 12. 5-axis simultaneous control N.A. N.A. (31i-B5)

8. Sequence Number N5-Digit Without hardware included

9. Absolute / Incremental Programming G90 / G91 13. AI contour control II (AICC-2, G05.1, 200 blocks) * 2 Std. Std. Std.

10. (Pocket Calculator Type) Decimal Point Programming Std. 14. Look ahead block expansion (1000 blocks in total) * 2 N.A. N.A.

11. Input Unit 10 Time Multiply Std. 15. Tool load monitoring (with Victor own PLC)

12. Plane Selection G17, G18, G19 16. Programmable mirror image (G50.1)

13. Rotary Axis Designation Std. 17. Bi-directional Pitch Error Compensation

14. Rotary Axis Roll-Over Function Std. 18. Addition of tool pairs for tool life management 512 sets N.A.

15. Polar coordinate Command G16 19. Cylindrical interpolation (G7.1) (used on 4th-axis) Std.

16. Coordinate System Setting Std. 20. Interruption type custom macro N.A.

17. Automatic Coordinate System Setting Std. 21. Addition of work-piece coordinate systems 300 sets N.A. N.A.

18. Work piece Coordinate System G52, G53, G54 ~ G59 22. Exponential interpolation (G2.3) N.A. N.A.

19. Addition of Workpiece Coordinate System Pair 48 Pairs 23. Smooth interpolation N.A. N.A.

20. Manual Absolute On And Off Std. 24. Spiral/conical interpolation N.A. N.A.

21. Optional Chamfering / Corner R Std. 25. Polar coordinate interpolation N.A.

22. Programmable Data Input G10 26. Floating reference position return N.A. N.A.

23. Sub Program Call 4 (0i/32i) or 10 (31i) folds nested 27. Hypothetical axis interpolation (G07) N.A. N.A.

24. Custom macro B Std. 28. Tool retract and return (G10.6 with Victor own PLC) N.A. N.A.

25. Addition of Custom Macro Common Variables #100~#199,#500~#999 29. NURBS interpolation (only avail. in HPCC/RISC) N.A. N.A.

26. Canned Cycles For Milling G73 / G74 / G76, G80-G89, G98 / G99 *1. Block addressing time:

27. Small hole peck drilling cycle G83 - 2 ms for AICC-2 (0i-F/31i-B)

28. Circular Interpolation by R Programming Std. - 1ms for HPCC (max. cutting feed 60 m/min) (31i-B)

29. Program Format FANUC std. format - 0.4ms for AI HPCC and AI nano HPCC (150m/min) (31i-B) and AICC-2+ High speed processing (31i-B)

14